December 2006 Digest

December 2006 saw major developments in the commitment of whole industries to a new paradigm shift to renewable energy.

December 2006 saw major developments in the commitment of whole industries to a new paradigm shift to renewable energy.

On the heels of last month's release of the forest products industry report called the Forest Products Industry Technology Roadmap several wood chip refinery press releases and wood industry reference sites became articles in the blogosphere. There were also two auto shows in Los Angeles that touted a new commitment to renewable energy propulsion systems including hybrids, electric cars, solar-powered, fuel cells, PHEVs, and flex-fuel vehicles.

The big news here is that the BIOstock Blog has a sponsor - Price BIOstock Services of Monticello, Arkansas. Originators of the BIOstock Services concept, The Price Companies has joined other industry leaders in recognizing the value of informing the general public of breaking information concerning emerging technology trends.

Here are their most significant developments of December 2006, organized by Blog...

BIOstock Blog--------------

• New Hampshire Renewable Power Plant Burns Wood Chips

• U.S. D.O.E. Information on "BIOstock" & Legislation

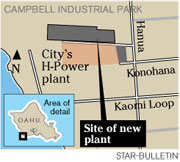

• HAWAII: Powering Paradise with biofuels

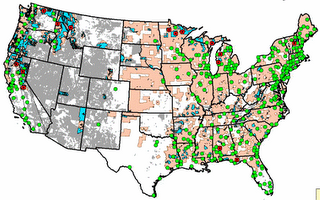

• Global BIOstock/BIOfuels Database

• Bioenergy Gateway: Energy from Wood

• Woody Biomass-to-Ethanol Demonstration Plant Contracted

• FLORIDA: Citrus Peels as BIOstock

• CANADA: Wood chips biorefinery venture announced

• Price BIOstock Services is a BIOstock Blog sponsor

BIOconversion Blog--------------

• Sugar Fermentation's Achilles Heel - Water

• James Woolsey on Biomass Conversion and PHEVs

• Decentralizing the BioFuels Industry

• NEW YORK: Cellulosic Ethanol Plant Demo Facility Contracted

• Xethanol's Cellulosic Ethanol Business Approach

• Bacteria - "Miniature Chemical Factories" Convert Waste to Ethanol

• Future Production of Liquid Biofuels

• Top Stories of 2006

BIOoutput Blog-----------------

• Carbon credits traded online

• "Mermaids' Tears" - Unrecycled plastic chokes the seas

• Alt Car Expo: A Day at the Beach

• A Tale of Two Auto Shows

New Feature

Each month we will provide a similar breakdown of December article titles from our favorite "companion" site - Biopact Blog. This list is kept current and is accessible in the right hand column of each of the three blogs.

Please forward a link to this digest to anyone you know who would be interested in keeping track of change that will affect us all. They can add their name to the mailing list on the BioConversion Blog.

technorati digest, biofuels, conversion, bioenergy, cellulosic, feedstock, ethanol