November 2006 Digest

Broadening the Scope - Focusing on Potential

Broadening the Scope - Focusing on Potential

The BIOconversion Blog - while keeping an eye on biofuel and biomass conversion technologies, facility deployments, and international issues - welcomes two new siblings! The BIOstock Blog covers biomass feedstock questions - what feedstocks are being used, how they are being transported, and what pre-processing technologies are being developed. The BIOoutput Blog focuses on the output of biomass conversion technologies - emissions, biofuels, electricity, green chemicals - and new uses for them.

The Digest will list the titles from all of them so don't worry about receiving 3 digests per month (whew!). However, those who use newsfeed software should link to all three because, in general, the articles will not be duplicated between sites. Here are this month's articles:

General Topics--------------

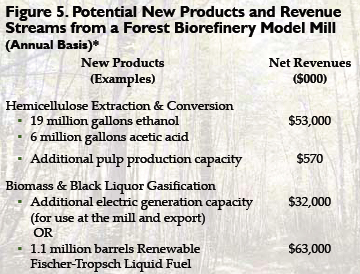

• Forest Industry: Bio-Solutions to Climate Change

• Harvesting Green Power

• Forests: Carbon S(t)inks?

• Investor's Roundup of Leading Cellulosic Ethanol Companies

• Expanded Recycling - a Key to Cutting Fossil Fuels and Global Warming

• Cellulosic Ethanol RD&D - Mascoma Corp. Raises $30 Million

• The Social Costs of the Status Quo

• U.S. D.O.E.: 5-year Plan for Biomass Conversion

• Renaissance of the Forest Products Industry

• Cellulosic Ethanol – Snake Oil for the new millennium?

• Upgrading Existing Plants for Biomass Conversion

• BIOplastics: BIOdegradable by-products of BIOconversion

• Colusa Completes Successful Rice Straw Harvest

• Cellulosic Ethanol from Woody Biomass

• Green Chemistry from Sugar Cane

Around the Nation--------------

• California Energy Commission PIER Grants for Biofuels RD&D

• CALIFORNIA: Cities favoring Gasification over Combustion

• CALIFORNIA: Enforcing Greenhouse Gas Emissions Limits

Around the World-----------------

• BIOstock of the Southern Hemisphere

• Impact of Global Growth on Carbon Emissions

Please forward a link to this digest to anyone you know who would be interested in keeping track of change that will affect us all. They can add their name to the mailing list on the BioConversion Blog.

technorati digest, biofuels, conversion, bioenergy, cellulosic, feedstock, ethanol